Price 1000000.00 आईएनआर/ Plant

MOQ : 1 Plant

Specification

- बिजली की आपूर्ति

- Electrics

- एप्लीकेशन

- Industrial

- उपयोग

- Industrial

- टाइप करें

- मटेरियल

- Water / Liquid

- सहायक पैकेजिंग मशीन का प्रकार

- क्षमता

- लीटर/घंटा

- कम्प्यूटरीकृत

- स्वचालित ग्रेड

- कंट्रोल सिस्टम

- ड्राइव टाइप

- वोल्टेज

- वोल्ट (v)

- रंग

- वारंटी

- 1 Year

Trade Information

- Minimum Order Quantity

- 1 Plant

- एफओबी पोर्ट

- FOB Port means that the seller is responsible for delivering the goods to a specific port of shipment. The seller covers the costs of transportation to the port and loading the goods onto the ship. Once the goods are loaded onto the ship, the risk and responsibility for the goods transfer to the buyer.

- भुगतान की शर्तें

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

- नमूना उपलब्ध

- No

- नमूना नीति

- मुख्य निर्यात बाजार

- मुख्य घरेलू बाज़ार

- प्रमाणपत्र

- To ensure the quality and safety of mineral water, a mineral water plant typically requires several certifications. Here are some of the most important ones: 1. BIS Certification (Bureau of Indian Standards): Mandatory for packaged drinking water in India. Ensures adherence to quality and safety standards. Covers both packaged drinking water and packaged natural mineral water. 2. FSSAI License (Food Safety and Standards Authority of India): Essential for any food business, including mineral water plants. Ensures compliance with food safety and hygiene regulations. Requires regular inspections and audits. 3. Pollution Control Board (PCB) Clearance: Necessary to ensure environmental compliance. Requires proper waste disposal and effluent treatment. 4. ISO Certifications (International Organization for Standardization): Optional but highly regarded. ISO 9001: Quality Management System ISO 14001: Environmental Management System ISO 22000: Food Safety Management System 5. State-Specific Licenses and Permits: May vary depending on the state or region. Often include health licenses, trade licenses, and local body approvals. It's important to note that specific certification requirements may vary depending on the country and local regulations. Always consult with local authorities and regulatory bodies to ensure full compliance. By obtaining these certifications, mineral water plants can demonstrate their commitment to quality, safety, and environmental responsibility, building trust with consumers and regulatory agencies.

About

- Capacity: 500 PPH

- Product Size: Up to 300mm x 200mm x 150mm

- Film Type: PVC

- Film Width: 500mm

- Heating Method: Infrared

- Cooling System: Air

- Automation Level: Semi-automatic

- Material: 304-grade stainless steel

- Power Requirements: 220V, single-phase, 50Hz

- Dimensions: 2m x 1.5m x 1m

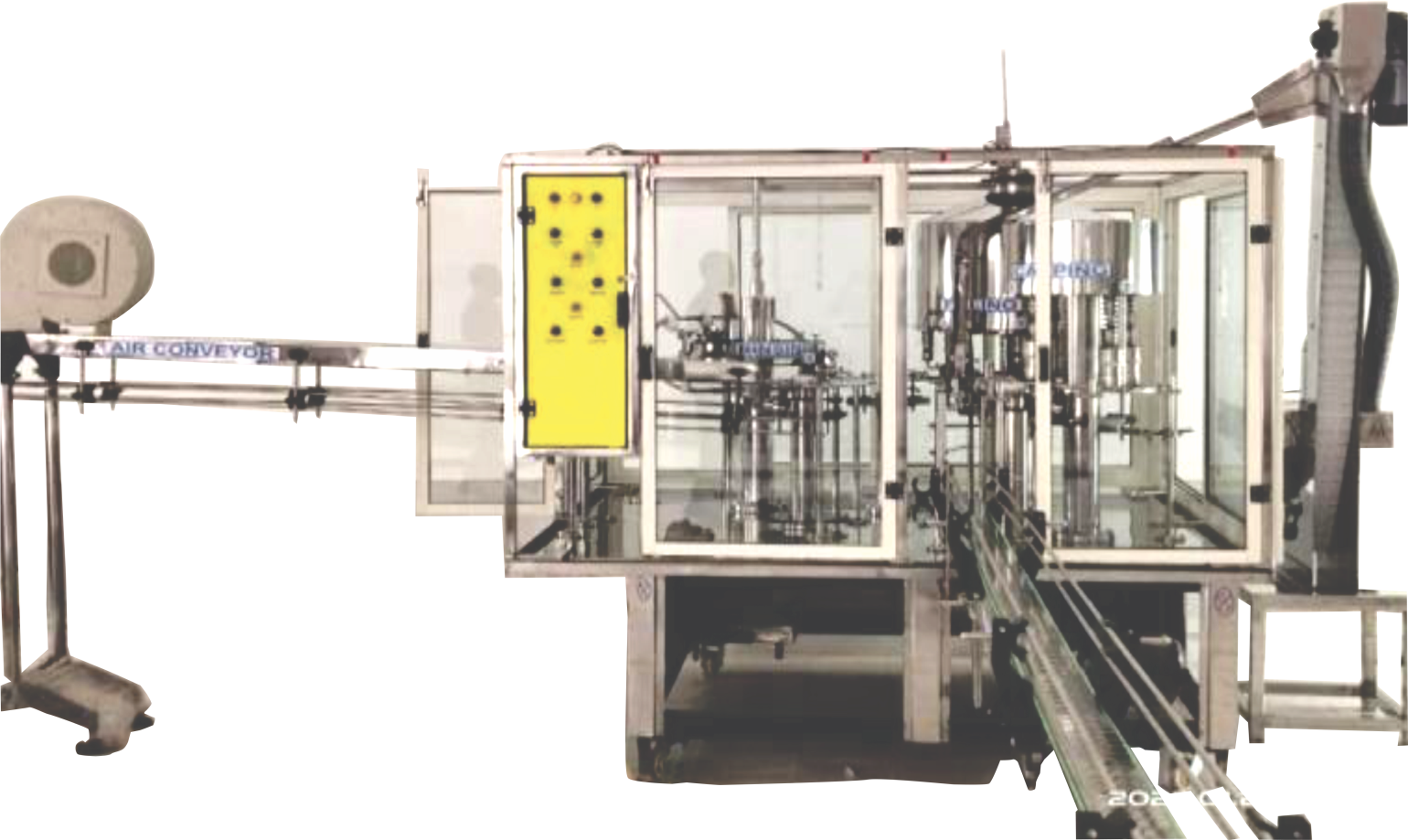

Advanced Water Purification and Bottling

Our industrial water purification plants are equipped with sophisticated filtration and reverse osmosis units, ensuring every bottle meets stringent quality standards. The fully automatic systems streamline the entire packaging process-right from purification to capping-significantly minimizing manual effort and maximizing efficiency. The computerized control system enables precise monitoring, reducing errors and downtime.

Reliable Capacity and Performance

Designed for demanding environments, these plants operate at speeds between 24 BPM to 120 BPM. This versatility makes them ideal for a wide array of businesses, from emerging suppliers to established exporters. The electric drive and robust HMI ensure stable output, minimal maintenance, and energetic efficiency, supported by a comprehensive one-year warranty.

FAQ's of Mineral water plant / Bottled water plant / Water purification plant / Water bottling facility / Reverse osmosis plant / filtration plant:

Q: How does the automated mineral water plant operate?

A: The plant operates using computerized controls and a Human Machine Interface (HMI), managing water purification, bottling, and packaging automatically. The electric drive powers the system, ensuring consistent workflow from water intake through multi-stage filtration and reverse osmosis, on to bottling and final packaging.Q: What is the typical process flow for water purification and bottling in this facility?

A: The process begins with raw water intake and passes through pre-filtration, reverse osmosis, and additional purification stages. Purified water is then conveyed to bottling lines where it is filled, capped, and packaged without human intervention, maintaining high hygiene standards throughout the process.Q: When should maintenance be performed on the plant systems?

A: Routine maintenance is recommended according to the manufacturer's guidelines, typically involving regular inspection of filters, reverse osmosis membranes, and electrical components. The computerized system provides alerts for necessary maintenance tasks, ensuring continual, smooth operation.Q: Where can this water purification and bottling plant be installed?

A: This facility is best suited for industrial environments such as manufacturing units or packaging centers with adequate space, electric supply (220-440 Volt), and proper water source connections. It is widely used by businesses across India and by export-oriented suppliers.Q: What are the main benefits of using a fully automatic water bottling plant?

A: The key benefits include high productivity, reduced manual labor, consistent product quality, and minimized human error. The advanced automation also ensures sanitation, efficient use of resources, and easy scalability for growing production needs.Q: Who typically uses this type of water plant in India?

A: Manufacturers, exporters, and suppliers in the beverage, food, and industrial sectors most commonly utilize these plants, especially those requiring large-scale, reliable, and hygienic water bottling solutions.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें